Many firms struggle today to stay afloat as restrictive bank lending, rising problems collecting receivables, and reduced consumer and business demand have combined to make running a profitable business very difficult. Companies surviving and thriving in this environment are going back to the basics and analyzing every aspect of their operations and supply chain – and one of the first areas that should be examined is Accounts Payable.

Over Payments: Sloppy Accounts Payable or Fraud?

Regardless of the business size, payments to vendors represent the single largest category of spending in most companies. While email and e-commerce make business communications faster and easier, a considerable amount of paperwork is still generated and must be linked to the relevant contract.

The issue is not paying an invoice twice; the problem is when the vendor –deliberately or by accident – overcharges your business by invoicing incorrectly or by adding fees outside of the contract – with freight bills being the largest source of incorrect payments. Do you know what the codes in the freight rate sheet mean?

- Invoices & Routing: Even the most sophisticated logistics and supply chain operations can be plagued by vendor errors that directly affect profits. Industry experts estimate that inaccurate freight bills and a failure to comply with established routing guidelines can add an estimated 6% to annual shipping costs.

Whether you ship goods around the world or to the next town, auditing for freight compliance can help you identify overpayments and inconsistencies such as fuel surcharges, non-adherence to a freight contract, selecting the wrong carrier, or the wrong shipping method.

- Audit-Audit-Audit! Auditors help you find and recoup duplicate payments, use credit memos issued, and capture missed discounts and a host of other errors that can impact your bottom line. To ensure a more comprehensive audit, the more sophisticated auditors or accountants use software tools to scan procure-to-pay data and link invoices to contracts; this is the best way to catch those erroneous payments before they affect both cash-flow and bottom-line performance.

Profitable companies rely on routine audits to detect errors and recover dollars paid erroneously to vendors, with "routine" the operative word. Experience shows that the ability to recover dollars-overpaid drops drastically the longer it goes unchallenged after the invoice is paid, so it's essential to audit your payables regularly.

- Contract Compliance: Negotiating contracts with suppliers can be long and demanding. Still, when negotiations are complete, and the goods begin to flow, it's essential to trial the vendors' compliance with the new contract terms and prices – and the buyers must check the invoices for accuracy.

A recent study said that nearly 40% of the cost savings negotiated from suppliers never made it to their bottom line, negating much of the purchasing department's efforts. Often, human error is the cause as overworked Accounts Payable staff enters the invoice into their system without checking to see if the invoice reflects the new contract.

- Fraud is a growing problem for today's businesses, especially during difficult economic times.

The Association of Certified Fraud Examiners estimates that 7% of a typical company's revenues are lost to fraud each year. The problem in shipping is determining if a vendor's invoice with unwarranted fuel surcharges was added deliberately or dua e to 'computer error" – hence the need for constant auditing; once is an error; multiple 'computer errors' likely are deliberate.

While larger companies are more likely to employ sufficient staff to catch such issues, smaller companies must also instruct their bookkeepers or accountants to audit A/P for accuracy.

Jan 2018 Ocean Freight Rates at a Glance

Watch this 30-minute webinar to analyze the short and long-term ocean freight rate movements for three main trade lanes.

Preserve & Protect Your Bottom Line

A typical large corporation is said to buy 300 - 500 materials unique to its business and has multiple sources of supply for each to diversify the reliability of supply. It's a balancing act: does one put production at risk if signing a sole-source supply contract that minimizes paperwork, or does the risk of erroneous payments rise exponentially if multiple vendors are used?

Effective supply chain management today needs both an effective strategy for managing sourcing and shipping decisions as well as verifying the accuracy of the vendor's paperwork.

Proactive prevention lets you detect duplicate payments, take advantage of prompt discounts, and alert careless or fraudulent vendors. Proactively managed companies are moving beyond A/P's traditional audit-and-recover to focus on prevention. Instead of relying on conventional manual auditing, firms are utilizing specialized software that monitors their payment process. Such systems enable the company to correct errors before the Euros or dollars are paid out, making it unnecessary to chase credit memos or cash.

While strategic vision is needed to determine your company's long-term direction and goals, in today's challenging times, cash management is the tool that provides an honest look at how your company is performing and what financial resources are needed to reach those goals.

Look for Savings in All Stages of the Supply Chain

For sure, eyes should be peeled for invoice mishaps to ensure accurate freight rate costs. However, always remember that if complete visibility into freight costs is applied at all levels of the supply chain, savings can come in truckloads.

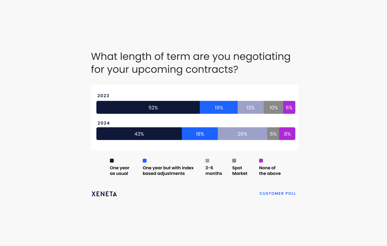

We at Xeneta can't stress enough the importance of having all the insight and intelligence needed when negotiating freight rates with your supplier. Make sure you know how the market is moving. What is the market average for my #1 trade lane? Am I getting the best rate from my supplier? Should I perhaps move X amount of TEUs to short-term or long-term contracts? Protect your bottom line - get smart with actionable metrics based on facts.

[Ebook]

Learn how Electrolux Uses Xeneta to Stay Competitive in the Container Shipping Market

.png)